LS2-3A-ALX Installation Guide

Getting Started

Unpacking

Working Area

Read Ahead

Box Contents

Control Panel

Piece Parts

Controller Overview

Connection Diagram

Pre-wiring

Units are delivered in a pre-wired

state, connecting power, relay, and triggered outputs. Do not remove any of the existing wirings

unless instructed by Latitude Security.

Installation Preparation

Tools

Cable

Pre-Install Checklist

- Working Internet connection (Ethernet or Wi-Fi)

- All required permits have been applied for and

approved by the proper authority

- Install site has no hazardous working conditions

- Electric lock(s) are operational and use 12-24VDC power

- THESE INSTRUCTIONS HAVE BEEN READ IN ENTIRETY PRIOR TO ATTEMPTING TO INSTALL

Physical Inspection

- Identify the location where the LS-2 enclosure

will be mounted.

- Near a standard

110 VAC outlet

- It should be central to where cabling can be

easily routed to/from.

- Although the enclosure is tamper-proof, it is

good practice to place it in a secure area to avoid tampering and/or being out of reach.

- Avoid high humidity

- Avoid extreme heat or extreme cold

- Identify the location of the card reader or PIN

pad.

- Mount within 6” of the same height as the door

handle

- Mount near the door

- Mount on the UNSECURE side of the door (outside)

- Identify cable routing

- Any visible cable should be 8’ or higher

- Cable below 8’ should be in conduit, wire mold,

or inside a wall

- When factoring distance includes vertical (height) distance

in addition to the span between enclosure and devices.

Cabling

Reader Cabling

Reader Mounting

Reader Connection

Use the wire colors according to the diagrams provided by the reader type. It is recommended that DOLPHIN

(blue) connectors or WAGO connectors are used to join wires between

the reader pigtail and cable going to the control panel. Please avoid using wire nuts. Dolphin connectors are good for fitting into

tight spaces, however, they are permanent connections and the wire must be cut

to redo a connection. Wago connectors

are preferred because they work with a wide range of wire gauges, and they don’t

require wires to be cut to redo a connection, although they may not fit in some

smaller areas.

Using Dolphin Connectors

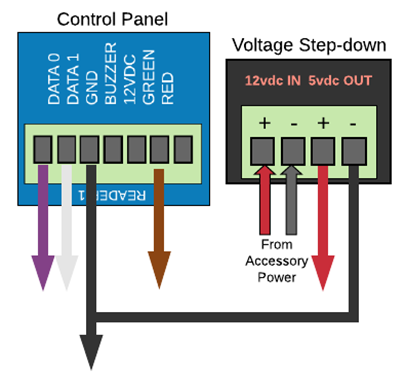

Control Panel Connections by Reader Type

IMPORTANT: Requires 5VDC power. Must use voltage step-down (~12v to ~5v) to

power reader.

Lock Cabling

Locks and exit devices should have a dedicated cable,

therefore, not to create any unnecessary electrical interference with the

reader, since the reader is a communication device.

Electric Strikes & Rim Devices

IMPORTANT: LOCKS MUST BE 12 VOLT DC ONLY

IMPORTANT: LOCKS MUST BE 12 VOLT DC ONLYDoor & Cabling Examples

Electric Strike with Lockset (mortise or cylindrical)

Magnetic Locks

Testing

- Power the system and wait about 3 minutes for

the system to fully boot prior to performing any tests.

- With the test card in hand, go to the reader and

scan the card.

- Did the light on the reader turn GREEN for 5

seconds?

- Did the door unlock and stay unlocked for 5

seconds?

- Test exit devices (typically with maglocks):

- Does the motion sensor unlock the door for 5

seconds?

- Does the button unlock the door? Depends on the setting, but unlock period

should be between 10-30 seconds.

- Contact Latitude Customer Support to complete

testing or troubleshoot any issues: +1(866)739-8588

Option: 2

Panel Status

Wi-Fi Configuration

- Computer (PC, laptop, or Mac) with Ethernet

(RJ-45) cable connection

- Ethernet patch cord

- The access control system must be powered on.

- Deactivate Internet connection on computer

(disconnect wi-fi, for example).

- Using patch cord, connect the computer to port

labeled ADMIN on the controller.

- Open an Internet browser and enter the

following IP address in the address bar: 192.168.207.1

- When prompted, enter the following:

- Username: cli

- Password: new5cli

- Navigate to Networking Admin Interface >> Networking >> WiFi.

- Make sure the Enable WiFi checkbox is checked.

- Enter the SSID

name of the network you want to connect to.

- Enter the WPA

Passphrase (password).

- Click Save.

- Disconnect computer from the control panel

Warranty & Support

Warranty

All hardware provided by Latitude Security carries a two-year (2) limited warranty from the commission date (printed on the front of the control panel). All installation services provided by Latitude Security, or its subcontractors have a one-year (1) warranty from the install date.

Customer Support Requests

- Customer Portal: https://support.latitudesecurity.com/

- Phone: +1 (866) 739-8588 option 2

- Email: support@latitudesecurity.com

Billing Inquiries

- Email: billing@latitudesecurity.com

- Phone: +1 (866) 739-8588 option 3